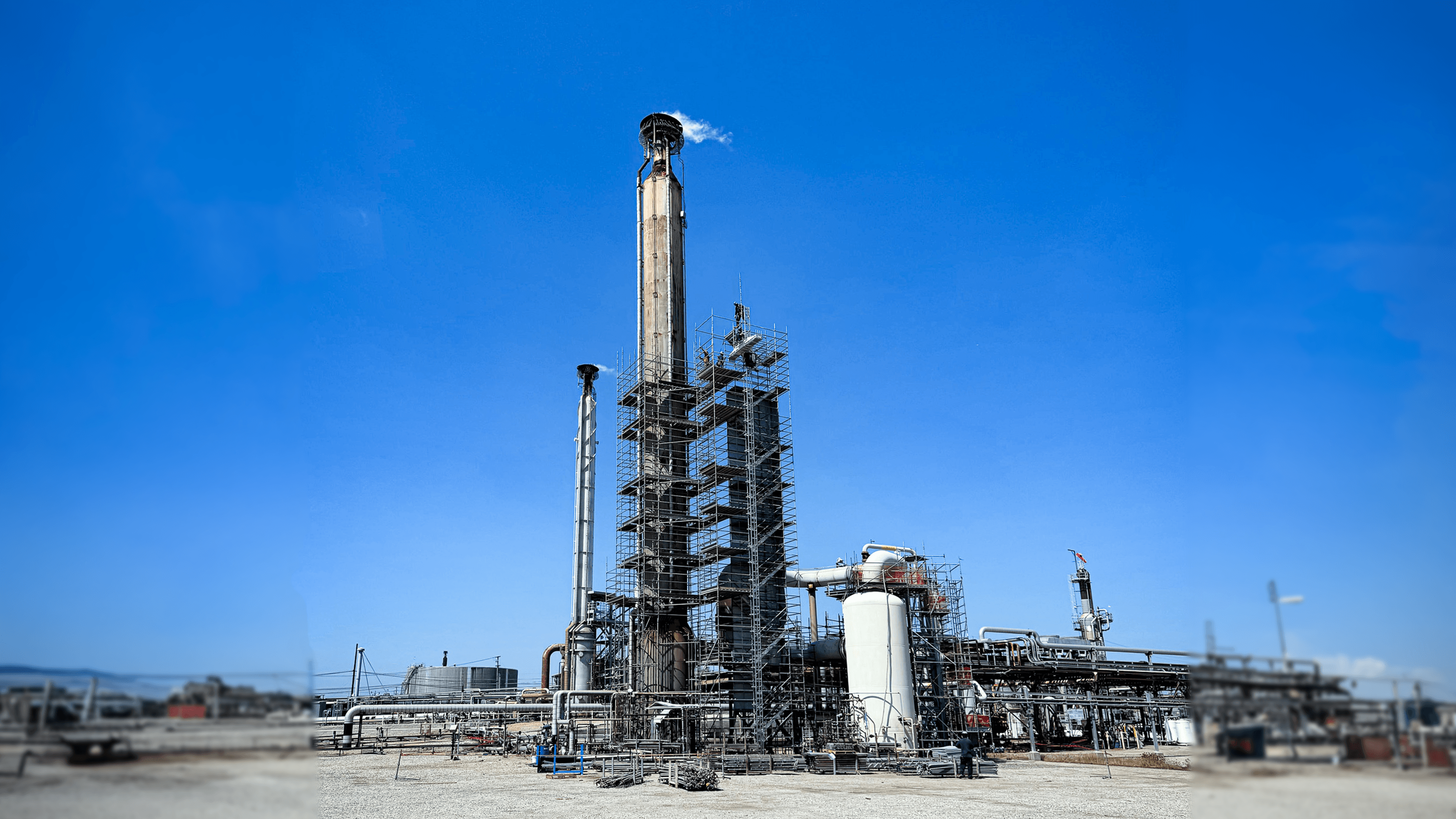

Immediate gains on your most critical jobs

Turnarounds, capital projects and maintenance done faster and safer

Asset owner

Reduce crane time.

Improve safety.

Contractor

Eliminate weather delays.

Bring more value to the client.

Field crew

Work safer.

Reduce end-of-day fatigue.