Project

BASF Ludwigshafen

Oct 6, 2024

Material Handling on Industrial Sites

Material handling is an essential part of every capital, maintenance, and turnaround project. Although traditional methods such as cranes and manual handling are widely used, they present challenges. Cranes require space that is not always available on tight industrial sites. The problem of finding enough skilled workers to keep up with demanding schedules is often encountered in the context of manual labor.

In response to these challenges, KEWAZO developed LIFTBOT, a battery-powered lifting robot originally designed for scaffolding assembly. Since 2024, the same LIFTBOT has supported insulation, painting, equipment transport, and more with its new transportation platforms. LIFTBOT has been deployed at iconic construction sites, including the U.S. Capitol, and major refineries like ExxonMobil Baytown.

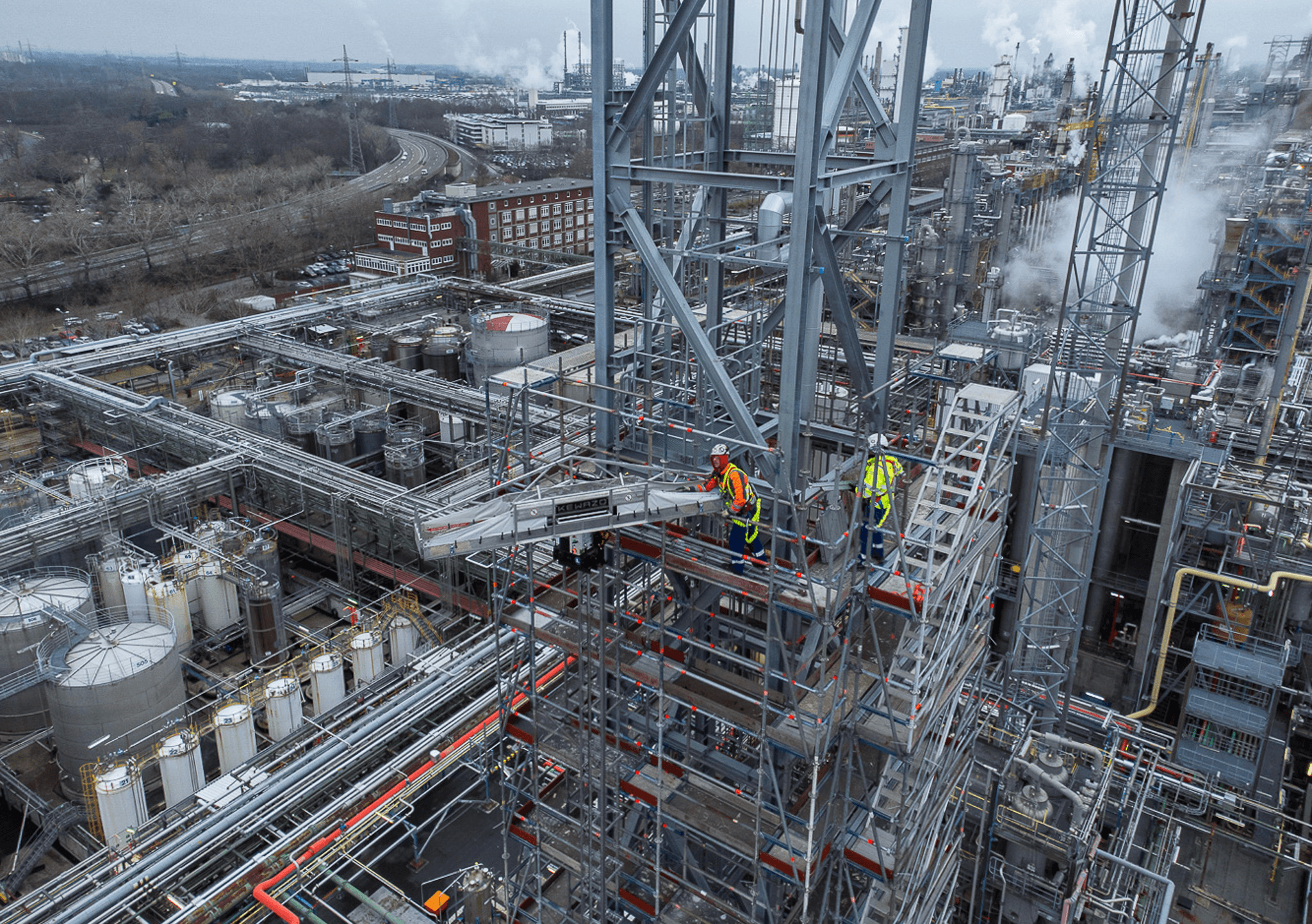

BASF Ludwigshafen, the largest chemical plant

BASF Ludwigshafen is the world’s largest integrated chemical production complex. It spans approximately 10 km² and includes more than 200 interconnected production plants. Nearly 39,000 people work at the site, supporting a wide range of operations from research and production to logistics and administration.

Crane Use for Scaffolding Assembly

For the assembly of a 52-meter scaffold flare on site, a crane was used. However, several challenges came with operating a crane at this height. Wind conditions made it difficult to safely load and offload materials.

Offloading materials from a crane at height (example footage, not BASF site)

Once wind speeds exceed safe limits, crane operations must be paused, which can impact the project timeline.

Robotic Solution for Scaffolding Disassembly

For scaffold disassembly, the team used LIFTBOT. Operating under a hot work permit in an ATEX zone, it was set up in just a few hours, including the installation of 50 meters of rails. The robot’s rotatable platform allowed scaffolders to remain inside the structure while loading and unloading materials, helping to maintain a high level of safety.

The team completed the disassembly efficiently and safely, without disruptions to site operations.

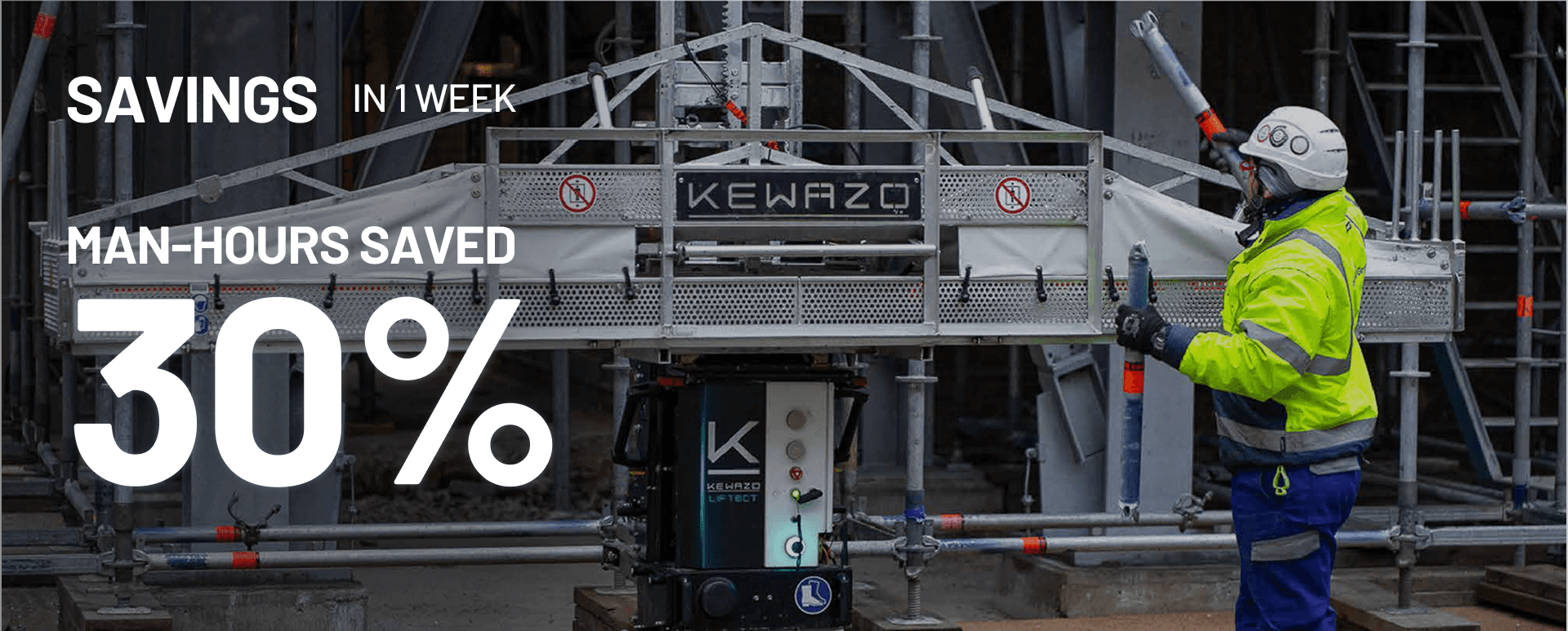

Results

LIFTBOT’s deployment resulted in a 30% reduction in man-hours. It enabled safe, continuous operation even in weather conditions that would have halted crane work.

Feedback

The scaffolders described the work as less stressful, and the entire team observed safer and more efficient operations at such heights. Here’s what they shared:

📎 Watch the project video in German

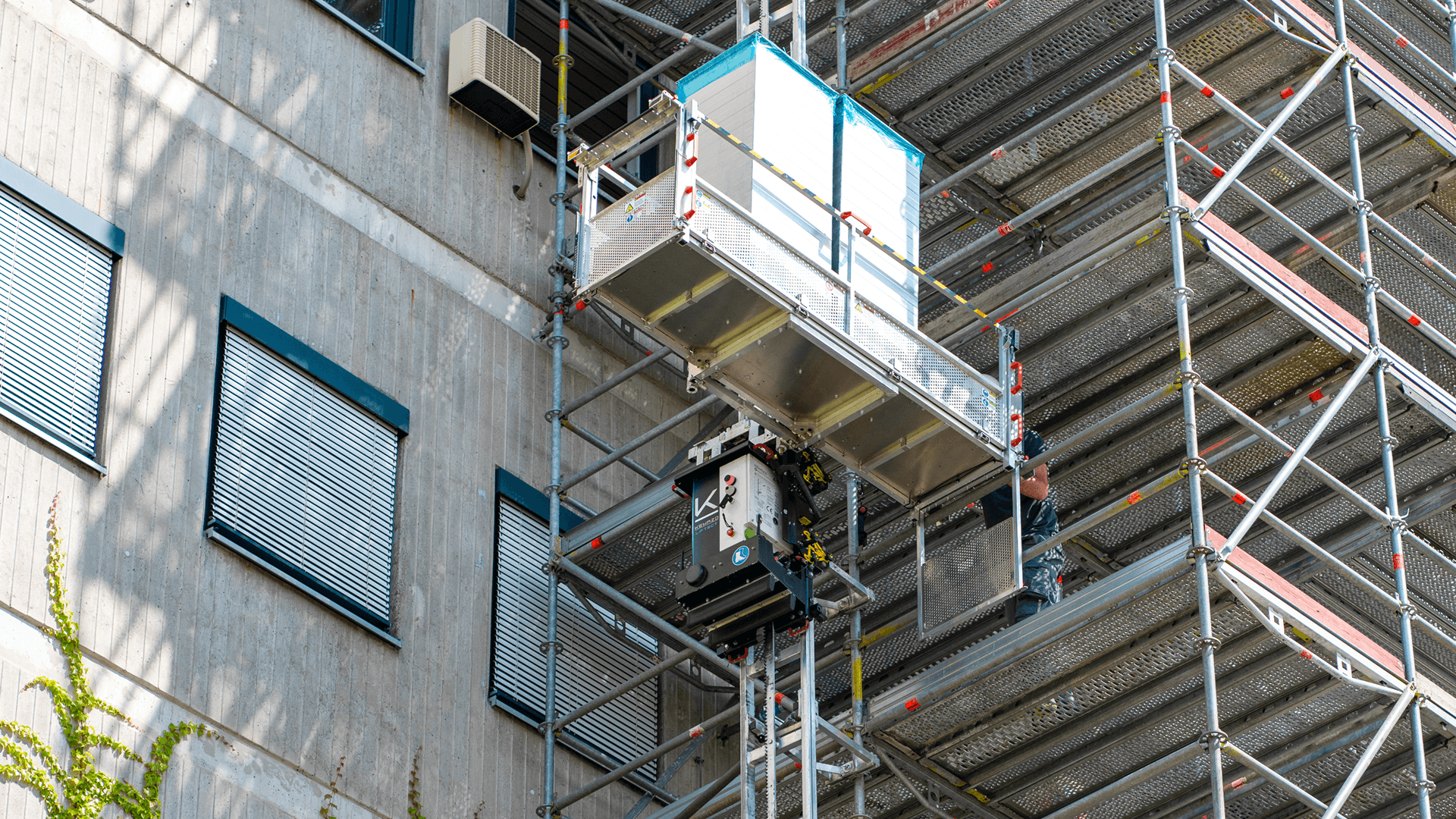

Beyond Scaffolding

In response to on-site needs, KEWAZO developed a new platform for LIFTBOT to handle a wider range of material handling tasks. At BASF, for example, LIFTBOT with its interchangeable platform was used for transporting ventilation, structural steel, and electrical work materials — all with the same robot.

LIFTBOT with general material platform at BASF

Cranes vs LIFTBOT: Choosing the right tool for the job

Cranes are often seen as the default for vertical material transport. But not every task requires one. In areas with limited access, at high elevations, or in windy conditions, alternatives like LIFTBOT can offer a more flexible and lower-risk approach.